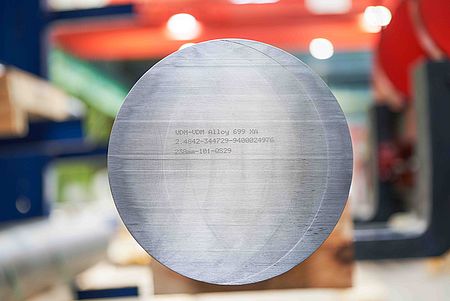

New ASME Code Case for VDM® Alloy 699 XA released

The American Society of Mechanical Engineers (ASME) has released a new Code Case for VDM® Alloy 699 XA (N06699), meaning the material is now officially approved for use in boiler and pressure vessels under metal dusting conditions at temperatures of up to 800 °C (1,472 °F). The new standard comes with the number 3111.

21 . October 2025

Within the ASME standardisation system, Code Cases contain permitted design parameters for boiler and pressure vessels of a particular material. “The design of pressure vessels is an everyday task for many of our customers, and ASME approval is a key requirement for widespread acceptance. Achieving this milestone has required a great deal of effort”, explains Dr. Helena Alves, Senior Vice President Research & Development at VDM Metals. Extensive tests over several years had to be carried out to provide the necessary data.

VDM® Alloy 699 XA is specifically designed for use in metal dusting conditions — a type of corrosion that can occur in the temperature range of 400 °C to 800 °C (752 °F to 1,472 °F) in gases containing hydrogen and carbon monoxide with low oxygen content. Compared to other nickel alloys that are used in carburizing environments such as VDM® Alloy 601 or VDM® Alloy 602 CA®, the chemical composition of VDM® Alloy 699 XA contains higher chromium contents, additions of aluminum and lower iron contents. Further to its high metal dusting resistance, the alloy offers outstanding oxidation resistance at high temperatures and creep resistance similar to that of Alloy 601.

Reduced maintenance costs

“Alloy 699 XA is the next-generation material solution for carburizing conditions. Field experiences from various petrochemical plants over the past couple of years have proven the excellent metal dusting resistance of the material. Our customers were extremely satisfied with the material’s performance and could even profit from reduced maintenance costs”, says Alejandra Lopez, Research Director at Tubacex. The company has been exclusively producing and selling seamless tubes made of Alloy 699 XA. Over the past years, more than one hundred tons of tubes, plates, bars, coil sheets and wires have been sold to various customers all over the world.

Various product forms available

Hot-rolled and cold-rolled sheets, welding wires and electrodes, forged billets and bars, rolled bars (manufactured by VDM Metals) and seamless tubes (manufactured by Tubacex) have been successfully produced. Furthermore, good weldability is achieved with the TIG arc welding process (GTAW) under argon with the matching filler metal VDM® FM 699 XA. The latest addition to the portfolio is a powder variant for additive manufacturing (VDM® Powder 699 XA). “With this wide range of products, we can support any kind of project – from replacement parts to maintenance to complete system designs”, explains Mr. Josefiak. The experienced application engineering teams from Tubacex and VDM Metals are available to advice on material specific questions.

Your contact